Plastic PEX piping systems are known defective products, in my opinion. And also, the opinion of the court system.

Some years ago, I wrote a series of articles about PEX piping and the unfolding issues around this product. They were really more of a recant from research of articles and videos I had done. Since then, I have received responses, stories and pictures literally from around the world as if I were some chemical expert. Let’s be clear, I am not. But…I can read. And…I can listen. I provide a 2-hour class on advanced plumbing topics including a long portion on PEX plumbing systems. I say systems because there are issues with not only the fittings but the piping itself. I continue to receive pictures from home inspectors around the country of failing and failed systems. Many of these are not old systems. They are less than 1 year old! Let me quickly go over some facts I have discovered.

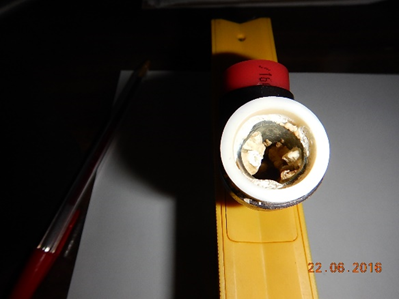

I remember issues with Kitec systems but those were, to my knowledge, a western US thing so I never really followed up much with those systems. The first class action lawsuit I remember focused on F1807 and Q PEX. This included specific systems from 1996-2010. It largely had to do with occlusion (blockage that reduces water flow) and something called dezincification. Dezincification is defined in this lawsuit like this,

“Dezincification is a process whereby zinc leaches from brass, which is an alloy of copper and zinc, thereby creating a white powdery buildup on the inside of the fitting and a weakening of the brass fitting. Dezincification can lead to, among other things, restricted water flow and an increased likelihood of the brass fitting leaking or breaking.”.

•http://www.plumbingfittingsettlement.com/

Let that sink in a bit. Dezincification is a chemical process during which the zinc is removed from the brass alloy when the alloy is exposed to water – the very substance these fittings are intended to convey!

Can you imagine…Derubberization, the chemical process during which the rubber is removed from your tires when the tires are exposed to asphalt. Would you ever think of buying a car that had a derubberization issue?

Chemical permeation

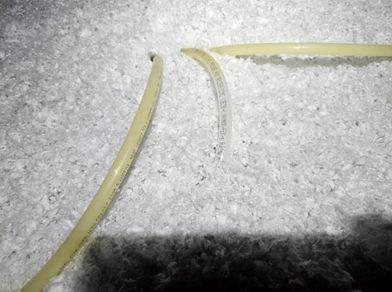

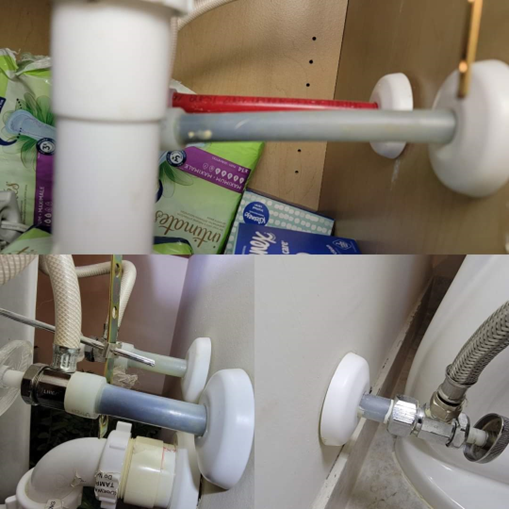

There was an EIR study done that proved down to the parts-per-billion, really nasty chemicals leach out of the PEX plastic into your drinking water. Not to mention lead leaching, yeah that’s an issue too. The report also discovered that chemicals like pesticides can permeate through the piping into your drinking water. Additionally, the study found that PEX pipe displayed biofilm on the interior of the pipe and promoted Legionella bacteria. I have included three pictures below of what I believe to be this biofilm. All pictures were taken at the same house at an 11-month inspection by Megan Keith. In other words, the home was less than a year old! Part of that report I read stated that polybutylene passed more stringent tests than some PEX systems and we all know the dismal historical performance of poly. Speaking of polybutylene and it’s poor performance, poly is an polyolefin based plastic. Guess what else is a polyolefin-based product…yep, PEX.

UV degradation

In Florida, often we have exposed piping where the service pipe comes underground from the meter by the street to the house where the pipe re-emerges vertical then turns into the house. No plastic pipes should be exposed because of UV degradation. With PEX piping this exposure can drastically reduce it’s resistance to chlorine (how the water is sanitized) and within 2 weeks, according to the EIR, completely reduces it’s resistance and the chlorine begins to break down the PEX plastic.

I keep mentioning the EIR report. It no longer exists! It has been scraped from the internet and replaced with another EIR that is the exact opposite of the original.

Chlorine degradation

During the manufacturing process, the material is infused with antioxidants to protect the PEX from chlorine degradation. These antioxidants are deteriorated by design so the longer the pipe is in service, the closer it is to failure. In other words, the “it’s been there for 5, 10, 15 or 20 years and we’ve never had a problem” excuse is a poor one. Someone that says that is telling you that the system is closer to failure today than it was yesterday.

In the Upinor law suit, in which they claim to be the “largest defective plumbing recall in US history”, I found this gem… “In court documents, Minnesota-based Uponor Inc. admits to selling defective, and dangerous plumbing fittings, but refuses to honor homeowner warranties.”

The “good” PEX

There have been multiple law suits for multiple systems so honestly, I’m unaware of a “good” PEX when you consider issues with the plastic piping, brass fittings, steel fittings, plastic fittings, dezincification, chlorination degradation, oxidation degradation, occlusion, chemical permeation, mechanical stress cracks and bacteria/mold growth. I mean like WOW. So how soon do all these things happen? Since we, as inspectors, typically only do inspections on brand new construction, 11 month inspections and at any point after that, we are seeing many signs of failures at the 11 month inspections but some court documents revealed failures within just a couple of months of install. There are many many variables here but you get my point. The failure process seems to happen right from the get go and they can’t get any better with time. If you are wondering about your house, we would be glad to do an inspection for you. As you know although a re-

plumb is expensive, it’s a whole lot less expensive than a re-plumb, a mold remediation, losing property and the rest of the inconvenience associated with a leak.

If you need a speaker, if you have cool pictures to share, if you have any old PEX laying around, contact me! If we all stick together, nobody gets burned.

We are located in Central Florida and would love to represent you, check us out at www.inspectagator.com or call the office to schedule an inspection today. Since we are a https://launchpadhomegroup.com/ brand, we have inspectors across the country. Our number is 407-678-4663. Our home inspection school offers home inspector training courses on many advanced subjects like mechanical, electrical, plumbing, pools, new construction, pre-drywall, defective building products and more. We conduct live on-site and on-line classes. Visit www.homeinspectionschoolflorida.com. Our YouTube channel is https://www.youtube.com/@homeinspections and as always, we appreciate your likes, subscribes and shares!